Introduction:

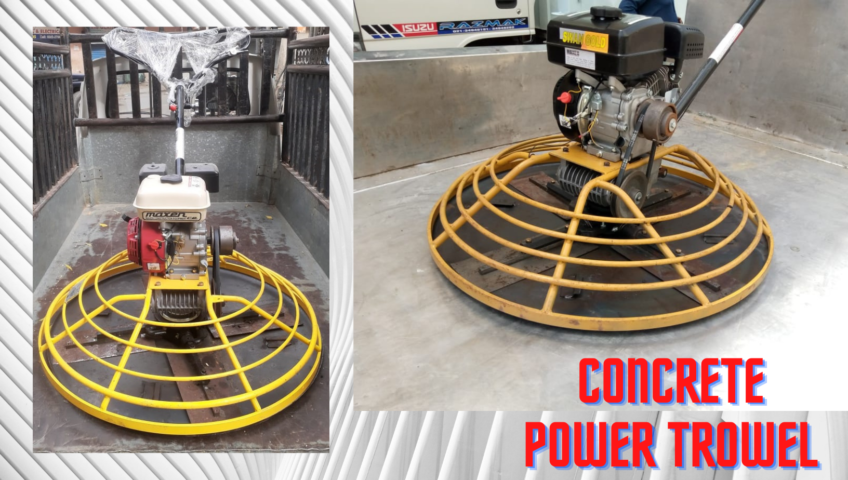

Conventionally concrete slab finishing which is seen and done using hand held trowels is now largely replaced by mechanical trowels also known as power trowels or concrete power float. We will highlight this aspect and how and where concrete power trowel is used in Pakistan construction scene. We see power trowels mostly on building projects, public infrastructure projects and concrete corridors etc. where concrete slabs are laid in general.

How a concrete power trowel works?

Let’s first briefly understand how a power float looks like. The anatomy of power trowel machine is inspired from a manual hand trowel. The trowel machine frame consolidates 4 trowel blades in a circular ring pattern coupled with the main gear unit. Once the gear unit gets power it transfer the same downwards to the trowel blades assembly and the 4 blades start rotating 360 degree. The momentum builds up and the concrete power trowel blades start rubbing the concrete slab gently. The resulting friction between the concrete surface and machine makes the machine float in multi direction. A trained technician handles the machine around the concrete surface or concrete panels and also adjusts trowel blades angle on the move through blade’s wire control on machine’s handle. In some cases a concrete compaction disc pan is used, affixing the disc’s brackets with trowel blades. The trowel blade rotation makes the disc rotate 360 degree. A trowel disc is like a circular pan with weight and smooth surface typically used when concrete is wetter. If the disc is used in the first place, a round of machine without the disc is done later on resulting in a more compacted and better polished finish of the concrete.

Salient Benefits of Concrete Power Trowel:

How did power trowel gain popularity? It’s the result that matters. The floor finished by a mechanical trowel machine as compared to manual labor differs. It is well compacted due to the machine weight, better polished concrete due to steady 4 trowel blades action. Importantly enough the cracks and empty pours does not remain a possibility at large while there is a lot of time saving to add more. Have a quick look at more details and price of power trowel in Pakistan.

Types of Power Trowel Available in Pakistan:

There are 2 types of power trowels; a ride on power trowel and a walk behind power trowel. Ride on type is currently unfamiliar to the Pakistan market while the latter one is popular. As the name suggests, a ride on power trowel allows the operator to sit on the machine’s driving seat while working. On the other hand a walk behind trowel has a handle which the operator holds and the operator walks with the machine as it works. Get in touch for more details of flooring tools and best construction equipment in Pakistan.